What is an HMI?

A human-machine interface (HMI) is a user interface or panel that connects a person to a machine, system or device. While the term can technically be applied to any display that allows a user to interact with a device, HMI is most commonly used in the context of an industrial process.

In industrial environments, HMIs can be used to:

- Visualize data visually

- Track production time, trends and labels

- Monitoring the KPIs

- Monitor the inputs and outputs of the machine

HMIs come in a variety of forms, from displays built into machines, to computer monitors, to tablets, but regardless of their format or the term you use to refer to them, their purpose is to provide information about performance and mechanical progress.

Common Uses of HMI

HMIs communicate with programmable logic controllers (PLCs) and input/output sensors to obtain and display information for users to see. HMI displays can be used for a single function, such as monitoring and tracking, or to perform more sophisticated operations, such as shutting down machines or increasing production speed, depending on how they are implemented.

HMIs are used to optimize an industrial process by digitizing and centralizing data for a viewer. By leveraging the HMI, operators can view important information displayed on graphs, charts or digital dashboards, view and manage alarms and connect with SCADA and MES systems, all through one console.

The importance of packaging machine’s configuration options

The flexibility in an automated box packaging machine and cartoning machine increases efficiency and offers more options for product and packaging variations.

Today’s consumers have busier lifestyles, causing many of them to replace standard meals with snack options, ready-to-eat and prepared meals. To address this trend, many snack and food manufacturers are offering a wider variety of flavors and portion sizes, so product runs can sometimes be shorter, making changeover time a more important factor.

Combining this trend with the increasing difficulty in obtaining a reliable and skilled workforce, many snack manufacturers are turning to automation.

Increased efficiency of Packaging Machines due to HMI

Beyond eliminating labor uncertainty, automated box packing machines are much more efficient and reliable than manual carton packers, so the incorrect count of bags in the case and the waste of the damaged product during packaging are no longer significant problems. Automated packaging machines ensure error-free speed, accuracy and efficiency, as well as improving employee safety and return on investment.

Automated cartoning machines are sophisticated and expensive, so selecting the optimal machine to buy is a significant investment. The machine must be reliable, match the design of your operation, be flexible to handle all of your products and packaging options, match your staff and their skill sets, and work seamlessly with your entire line of equipment. This blog addresses the importance of flexibility in handling your products and packaging options.

How they work

Automatic box cartoning machine can take a given instruction for different packing patterns in one case and load accordingly. Depending on the machine, a basic configuration is vertical rows of different lengths (depending on the size of the package). More advanced machines can also vary the vertical stacks and/or configure more complex patterns.

Automating the packaging of your box eliminates problems such as the introduction of foreign bodies or incorrect box counts, and fully automatic systems provide accurate packaging of boxes of mass-produced products, some with a capacity to pack up to 150 packages per minute.

Packaging Machines are becoming more “modern” thanks to HMIs

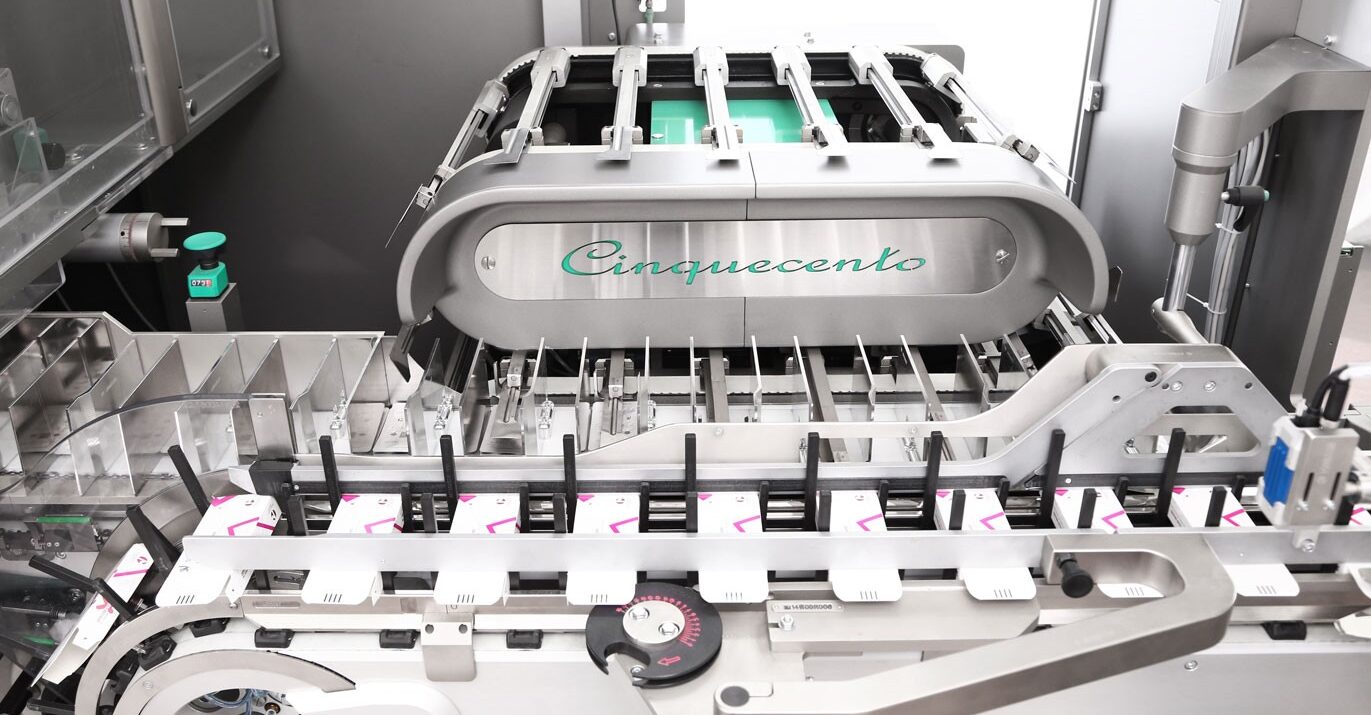

ÉLITER Packaging Machinery, one of the fast-growing packaging machine manufacturers in the world, has incorporated with their machines smart HMIs, especially with their cartooning machines which use sheet metal structure, is beautiful and simple, and easy to operate.7-8 servo drive systems, with independent control, feeding detection functions, glue detection, etc.Double servo advance and thrust control, stable and accurate cartoonAdopt motion controller, stable and reliable operation.

HMI with memory function, convenient for changing product specifications and boxes, easy to operate.A series of safety protection measures, fault self-diagnosis function, easy fault display.

The cartoning machine is mainly used to pack bakery food, snacks, frozen food, medicines, daily necessities and any other solid products automatically.The horizontal cartoning machine automatically completes the steps such as product feeding, carton assembly, carton cartoning with adhesive flap or carton carton with folding flap.

The qualified pass rate is high and the appearance is beautiful. Accurately and smoothly complete the cartoning action, which makes our cartoner has a wide range of applications in food, daily necessities, chemical, medical and other industries.

All of these smart and intelligent functions are realized thanks to the application of HMIs with the packaging machine.